The inevitable modernization of metal castings

Modern Foundry.

Tech-Enabled.

At Scale.

Fabri has vertically integrated AI, robotics, materials, and equipment to build software-driven foundries that cut lead times for high-precision metal castings to days, down from months or years.

The Unseen Backbone of Industrial Power.

Investment casting is the most widely trusted process for scaling complex, high-performance metal parts – such as turbine blades that survive under extreme stress and temperature for 10,000’s of hours in jet engines.

.jpg)

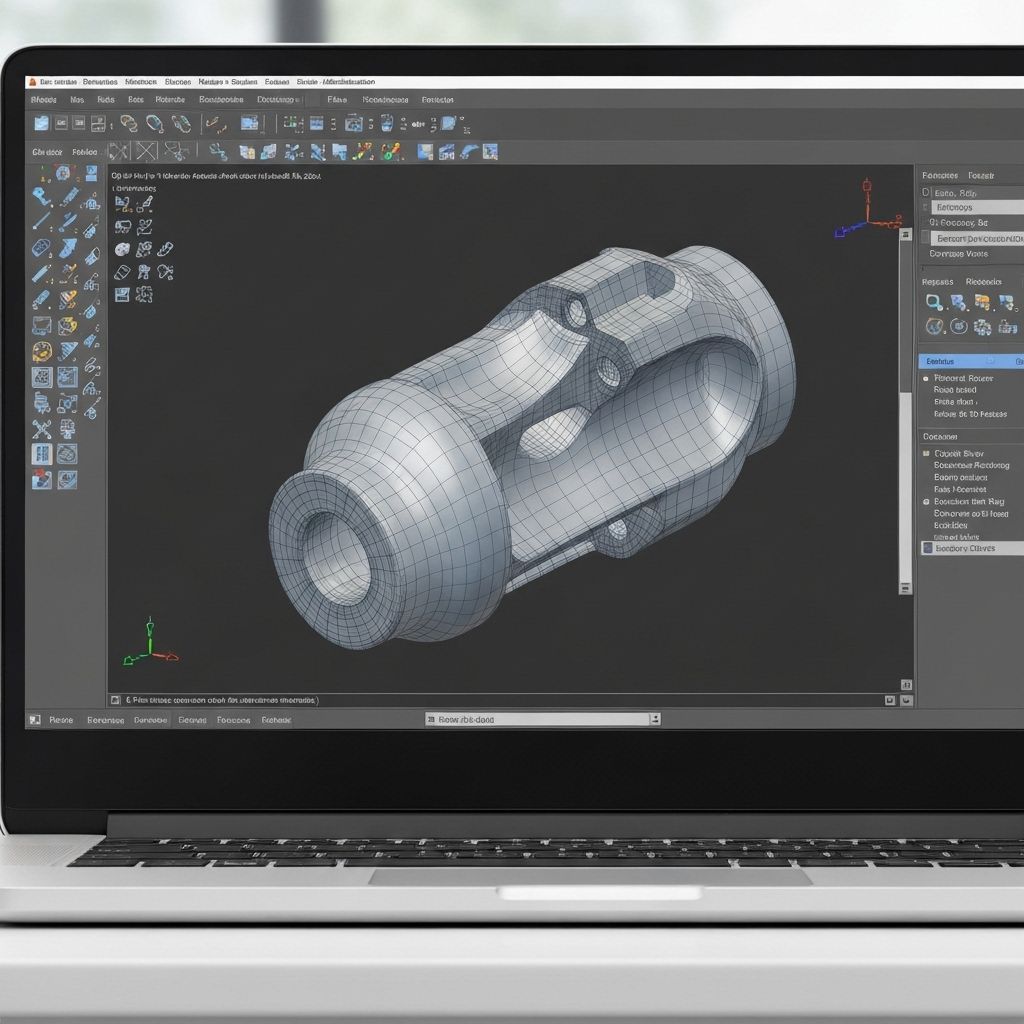

No Tooling

Rapidly iterate without tooling costs or delays.

No Human Variation

Our fully digital process ensures consistency and quality.

Rapid Turnaround

We typically ship parts in 5-10 days.

Seamless Scaling

Eliminate requalification triggers when moving from prototyping to production.

Design Freedom

Consolidate assemblies and enable generative design.

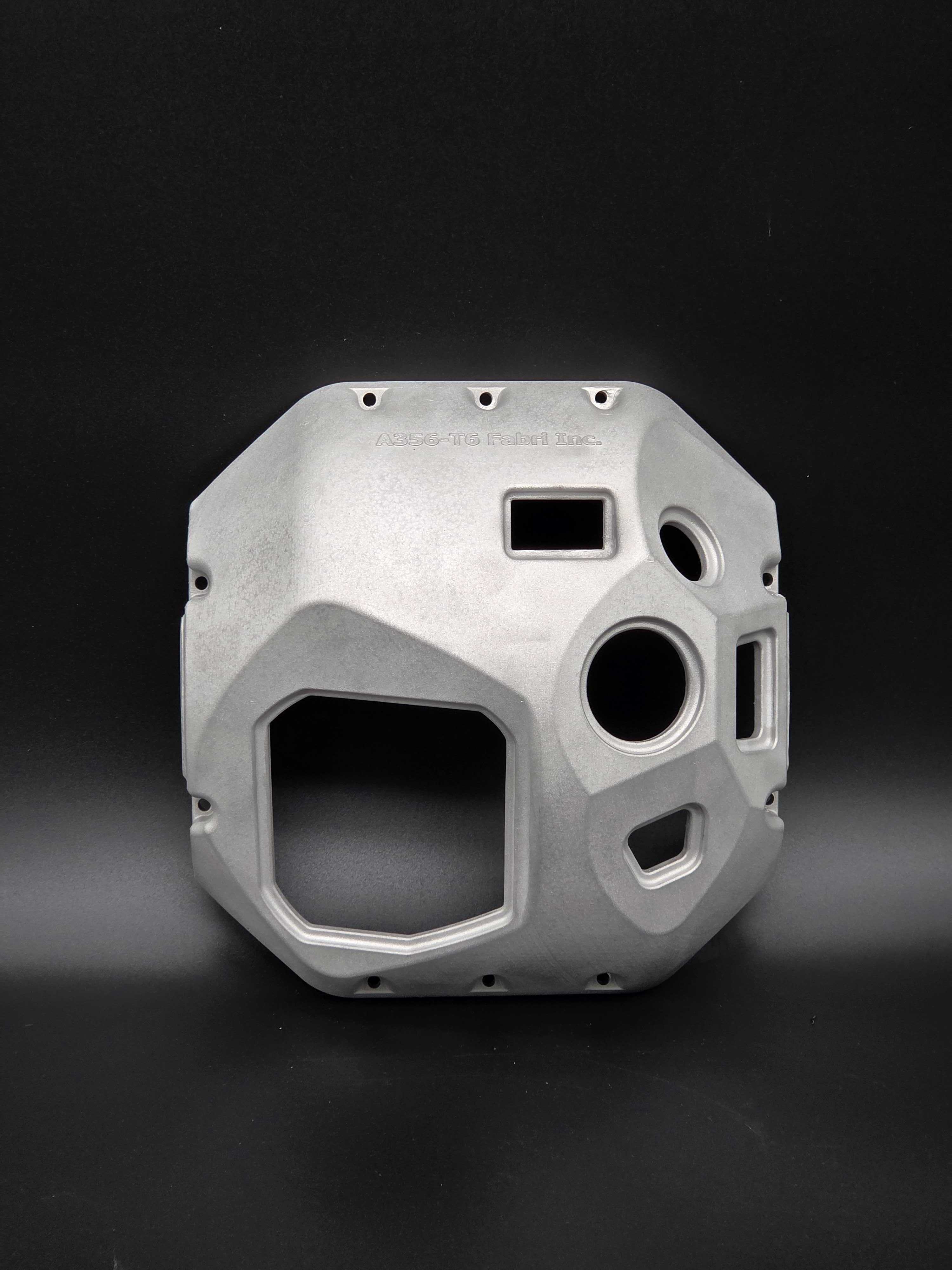

Aerospace Materials, Unmatched Precision.

| CAST ALLOYS | Aluminum Alloys (e.g. A356, E/F357, XK360, A380) |

| CASTING SIZE | 7 x 13 x 15.75 inches |

| TOLERANCES | Geometry-dependent. Typical: ±0.005in/in |

| SURFACE FINISH | 64-125μin Ra as-cast |

| AMS 2175 | Up to Class 1, Grade A |

| MIN ORDER QTY | None |

ITAR Registered | JCP Certified | NIST 800-171 Compliant | CAGE: 9N8E4

Need bigger parts or different alloys?

Ask us about our 2026 and 2027 capability expansions coming soon

Backed by Leading Investors

Fabri is proud to be supported by visionary venture capital firms who believe in our mission to modernize manufacturing through software and automation.

Transforming Manufacturing

With the backing of our investors, Fabri is revolutionizing the metal casting industry. Our software-driven approach delivers aerospace-grade castings in days instead of months, serving leading companies in aerospace, defense, and industrial applications.

About Us

Founded by experts in aerospace, software, and manufacturing operations

Steven Davis

Founder & CEO

At MIT, Steven founded Fabri and built a pioneering team to reimagine how advanced manufacturing can rebuild America’s industrial base. With experience at Relativity Space and roots in Los Angeles’ aerospace community, he unites technical rigor with entrepreneurial vision to modernize the foundry industry.

Pieter Coulier

Founder & CTO

Pieter blends deep research roots (PhD, KU Leuven; postdoc, Stanford) with startup and scale-up execution at Velo3D, where he co-developed support-free metal 3D printing. At Fabri, he’s assembling a world-class team to modernize investment casting with software and automation and rebuild industrial capability.

Tom Cole

Founder & COO

An MIT-trained mechanical engineer, Tom has built his career around manufacturing and entrepreneurship. After starting out at GE, he co-founded Atlantis Components, which was later successfully acquired by AstraZeneca. At Atlantis, Tom led, built or integrated high-tech manufacturing facilities in Europe, Asia and the U.S. As Vice President of Operations at Inkbit, he established their printer manufacturing facility and launched the company’s Digital Factory.

Open Positions

We're always looking for exceptional talent across engineering, manufacturing, and operations.

Explore All Opportunities

From software engineers to manufacturing specialists, we're building a world-class team. View our current openings and apply directly through our careers portal.

View All Open Roles